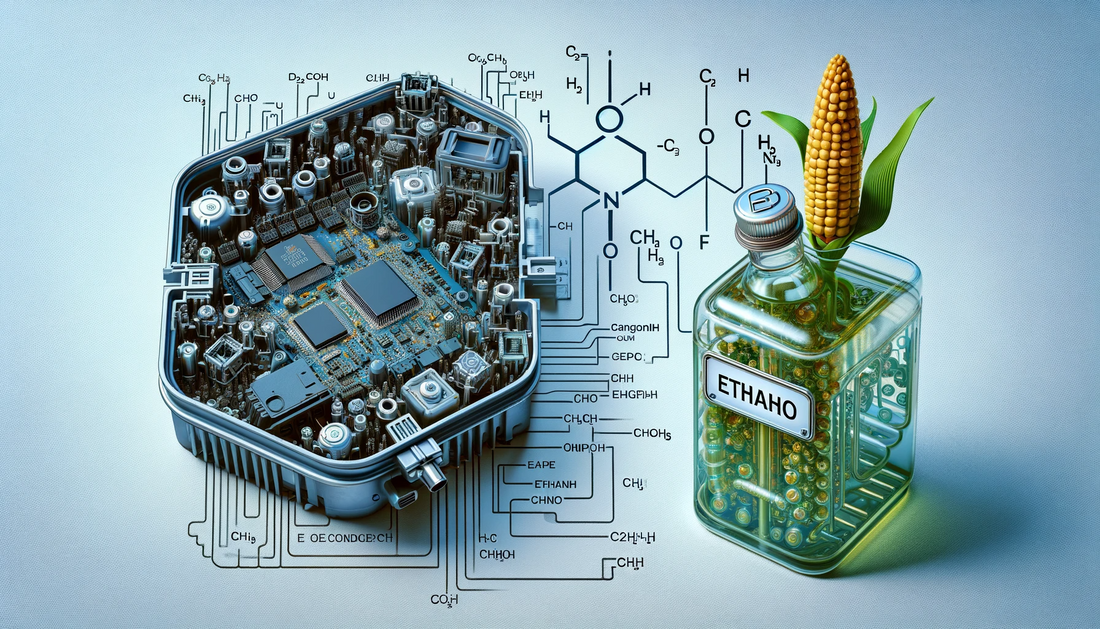

The Ram TRX, a high-performance vehicle, is a marvel of modern automotive engineering. However, its ability to use flex fuel, specifically blends like E85, is limited due to several technical reasons related to its GPEC2 Engine Control Unit (ECU).

ECU Calibration and Air/Fuel Ratios: The heart of the matter lies in the GPEC2 ECU's calibration. This system is optimized for gasoline, which has a stoichiometric air/fuel ratio of 14.7:1. Ethanol, on the other hand, particularly in E85 blends, has a significantly different stoichiometric ratio, around 9.8:1. This difference means the engine requires more fuel per unit of air when burning ethanol compared to gasoline. The GPEC2 ECU, as it stands, cannot dynamically adjust the fuel mixture and ignition timing to accommodate this difference.

Fuel Composition Sensing: Flex fuel vehicles typically feature sensors to detect the ethanol content in the fuel and translate that into the ECU. This capability allows the ECU to adjust engine parameters for optimal performance with varying ethanol blends. Let's break this down further shall we?

Measuring Ethanol Content:

The sensor is typically located in the fuel line and uses a small turbine or other flow-measuring device to determine the proportion of ethanol to gasoline.

It does this by measuring the capacitance and conductivity of the fuel. Ethanol and gasoline have distinct dielectric properties, so the sensor can determine the ethanol percentage by measuring these properties.

Transmission of Data to the ECU:

The sensor outputs a frequency signal proportional to the ethanol content. The ECU is programmed to interpret this frequency. For example, on general motors flex fuel vehicles frequency is measured between 50hz and 150hz, where 50hz is 0% ethanol and 150hz is 100% ethanol. So assuming a 60hz signal, thats 10% ethanol content displayed on the gauge, 100hz signal is 50% ethanol content etc.

This signal is sent over the vehicle's data bus, which could be a CAN (Controller Area Network), LIN (Local Interconnect Network), or other proprietary communication system, depending on the vehicle's design.

ECU Response:

Once the ECU receives the data, it adjusts the engine's operation accordingly. This includes changes in fuel injection timing, quantity, and ignition timing to accommodate the different combustion characteristics of ethanol compared to gasoline.

The ECU uses tables or maps loaded into its software that correspond to different fuel compositions. It uses these maps to make real-time adjustments to optimize the engine’s performance for the specific fuel mix.

Closed-loop Feedback System:

The ECU also monitors the engine's performance through other sensors, like the oxygen sensor, to ensure the fuel is burning efficiently. This forms a closed-loop system where the ECU constantly adjusts the engine parameters based on the data it receives from the ethanol content sensor and other engine sensors.

This sophisticated system allows flex-fuel vehicles to adjust their engines on the fly to run efficiently on a wide range of ethanol and gasoline mixtures, from pure gasoline to E85 (85% ethanol and 10% gasoline) or any blend in between.

The GPEC2 ECU in the Ram TRX lacks this flex fuel sensing ability, making it unable to automatically adapt to the changing fuel compositions that flex fuels present.

Ignition and Knock Control: Ethanol's different combustion characteristics, including a higher resistance to knock due to its higher octane rating, also play a role. The GPEC2 ECU's ignition and knock control systems are designed around gasoline's properties. They might not be able to fully leverage ethanol's higher knock resistance or adjust appropriately for its different combustion properties.

Performance Optimization: The Ram TRX's engine is fine-tuned for maximum efficiency and power output with gasoline. Utilizing a different fuel type without corresponding adjustments can lead to suboptimal engine performance and could potentially cause damage. Here is a truck experiencing some issues trying to run flex fuel and how we addressed them

In conclusion, while the Ram TRX is a powerhouse in its domain, its GPEC2 ECU's current configuration and calibration for gasoline limit its ability to effectively use flex fuels like E85. To enable flex fuel compatibility, significant modifications would be needed, including reprogramming the ECU, adding a flex fuel sensor, and possibly altering other engine components. This s where the Demon 170's ECU comes into play and why many are so interested in the technology behind it. But that my friends is a conversation for another day.

We hope this write up brought value to your modding experience. Our shop prides itself on high level of customer service and transparency. Ram TRX Racing is a subsidiary of Wragth Motorsports and it is something we do on our own time and dime to help educate, inspire and bring the TRX community together. If there is anything we can ever do to serve your TRX needs, please fill out our quote request and we will jump on call to see how we can help. Click here to fill out the request now.

Thank you all for the support, and let's get show the world why the TRX is better than the Raptor R